Steam is widely utilized in the pharmaceutical industry for many heat transfer and sterilization processes. Rigorous control of steam generation chemistry is also necessary to prevent corrosion and fouling of equipment that could otherwise cause failures and process shutdowns.

Protecting Steam Generation Equipment from Corrosion

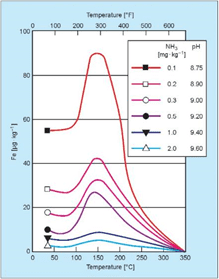

Boiler condensate/feedwater system treatment is a key aspect of protecting steam generation equipment. Typically, most of the piping in these networks is of carbon steel construction. Treatment programs are normally geared to minimize two primary corrosion mechanisms: general corrosion and oxygen attack. General carbon steel corrosion is often addressed by maintaining pH within a mildly alkaline range from near 9 to 10.

Figure 1. Influence of temperature and pH on iron dissolution from carbon steel. Source: Sturla, P., Proc., Fifth National Feedwater Conference, 1973, Prague, Czechoslovakia.

pH Conditioning

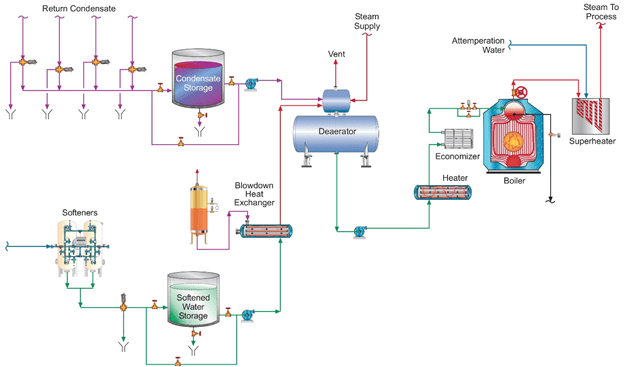

In the power industry, the common pH conditioner is ammonia, which raises feedwater pH via the following reaction:

However, ammonia is typically not preferred for systems where steam can touch food or pharma products. The most common alternatives are neutralizing amines, which are short-chain organic compounds with either an attached or embedded amine group.

Even then, only some of these compounds satisfy regulatory requirements, and they often have concentration limits.

Accordingly, treatment products and injection points should be selected with care, and residual concentrations should be monitored. ChemTreat’s experienced team can work with you to develop the best pH conditioning program for your facility. We can tailor a blended amine treatment specifically to your system needs.

Oxygen Corrosion

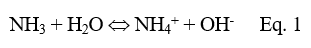

Most industrial steam generator systems include a mechanical deaerator (DA).

Figure 2. A common industrial steam generation layout. Note the makeup water and condensate return feeds to the deaerator.

However, the dissolved oxygen (D.O.) lower limit guaranteed by DA manufacturers is typically 7 part-per-billion (ppb) in the DA storage tank discharge. To further reduce D.O. concentrations in the boiler feedwater, many facilities feed a supplemental reducing agent, aka an oxygen scavenger.

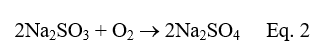

Oxygen scavengers common to heavy industry applications, such as carbohydrazide, hydroquinone, etc. are often not suitable for pharma facilities with low-pressure boilers. Non-volatile sodium sulfite (Na2SO3) is one alternative.

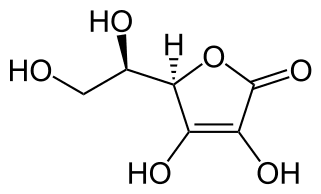

This product generally does not carry over in steam, unless poor boiler operation or malfunction of drum steam separator devices allows mechanical incursion of moisture into the steam. Another compound popular for D.O. removal in special applications is erythorbic acid.

Like sodium sulfite, it is a non-volatile reducing agent.

Contact us for assistance in designing a treatment program customized to your specific needs. Like all other technologies, due diligence is necessary to determine the feasibility for utilizing methods. Always consult your equipment manuals and guides and seek ChemTreat guidance to address your specific system needs..

Check out part 1 and part 2 of this series to learn more about water treatment for the pharmaceutical industry.