Minimize Water Usage and Waterborne Pathogen Growth

Hospitals and healthcare facilities look for effective water treatment that keeps their systems running well with minimal manpower requirements. ChemTreat’s experienced team designs custom water treatment programs that fit your facility’s unique needs while helping you minimize water usage and waterborne pathogen growth.

Get in touch to partner with us for your water treatment needs.

UNIVERSITY MEDICAL COMPLEX SAVES $500K IN ANNUAL WATER COSTS WITH CHEMTREAT PROGRAM

Supplemental Disinfection for Potable Water Systems

In the healthcare industry, managing waterborne pathogens in potable water systems is an integral part of a successful water treatment program.

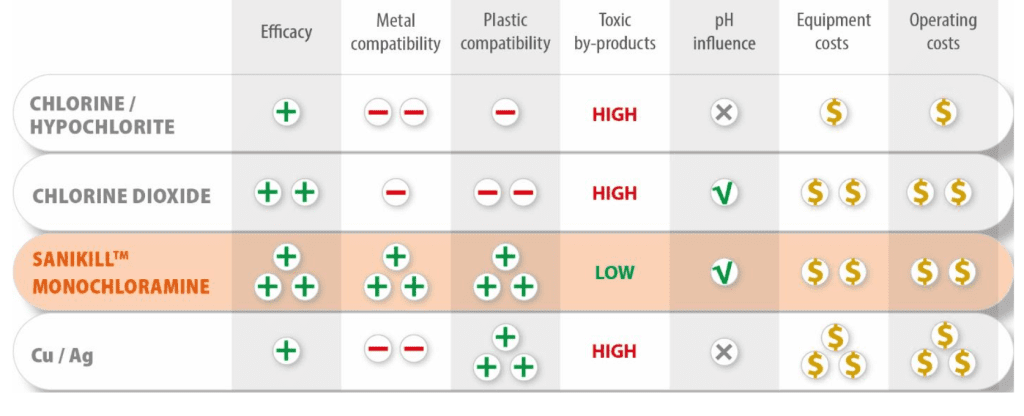

ChemTreat has partnered with Sanipur to offer SANIKILL®, a monochloramine-based supplemental disinfection technology for potable water systems. This patented technology offers many benefits over chlorine-based oxidizers and other industry-standard disinfection technologies.

- Improved waterborne pathogen control

- Better biofilm penetration

- No taste or odor problems often associated with chlorine-based disinfectants

- Lower observed presence of disinfection byproducts

With a lower oxidation potential than chlorine-based alternatives, SANIKILL can be used as a disinfectant for long periods without damaging potable water piping systems.

This technology provides automated on-site monochloramine production and treatment that can be monitored remotely and reduce handling requirements.

Cooling Treatment for Healthcare Facilities

Cooling treatment is a foundational aspect of our water treatment offering. We thoroughly assess your systems and create programs tailored to your facility’s needs. Our offerings can help your systems run at peak efficiency while extending asset life and reducing water usage.

Our cooling treatment capabilities include:

- Solutions to inhibit corrosion, scaling, and biofouling

- SpecOx® specialty oxidants for advanced microbial control

- Millicide® monochloramine-based treatment for difficult-to-treat recirculating and cooling process waters

- Cooling tower high-efficiency sand filtration and cleaning services

Smart Release®: The Next Generation of Solid Cooling Treatment Technology

Through our partnership with Dober, ChemTreat offers an alternative to liquid cooling treatment to help you reduce storage requirements and lower greenhouse gas emissions caused by freight shipping.

Benefits of Smart Release over liquid cooling treatment include:

- Reduced carbon emissions from shipping freight

- Quick delivery

- Small footprint for facilities with storage limitations and ergonomic packaging ideal for difficult-to-reach locations

- Decreased chemical exposure for your personnel

- Water savings thanks to the elimination of large drums that need to be triple-rinsed

Smart Release comes prefabricated on a stainless-steel frame that is easy to move with a pallet jack or a two-person team.

Feeders come equipped with motorized ball valves for chemical feed control. This allows treatment to be fed at accurate quantities, improving performance and reducing the potential for chemical overfeed or underfeed.

MAJOR HOSPITAL SYSTEM IMPROVES COOLING SYSTEM MONITORING AND CONTROL WITH SMART RELEASE® SECOND GENERATION SOLID TREATMENT TECHNOLOGY

Boiler Treatment for Healthcare Facilities

ChemTreat field engineers provide the highest level of boiler expertise available, and our technical specialists can offer guidance and recommendations for treating a wide range of systems. We can work with you to design a boiler treatment program to help you increase system efficiency, decrease downtime and maintenance costs, and extend asset life.

Our boiler treatment programs may include:

- Steam generator system evaluations

- Makeup water treatment

- Impurity ingress detection and corrosion protection for feedwater systems

- Internal boiler treatment to control corrosion and deposition

- Steam generator layup

- Water and steam chemistry monitoring

- Softener and RO system equipment and services

IMPROVING BOILER CONDUCTIVITY CONTROL AND INCREASING CYCLES AT A MEDICAL CENTER WITH CTVISTA®+

Environmental Services

ChemTreat is always looking for ways to help our customers reduce water and energy usage to minimize costs and meet environmental goals.

Our treatment programs help you maintain reliable heat transfer systems and improve water usage efficiency while significantly reducing resource requirements and the carbon footprint of your water treatment program.

LEED CERTIFICATION: HOW CHEMTREAT CAN HELP

Our R&D team is continually developing new chemistries and improving existing solutions to solve the unique water treatment problems our customers face. Our offerings include:

- Phosphate-free and zinc-free cooling water treatment options

- Non-metal and non-PBT chemistries

- Advanced formulations to reduce water usage and handle challenging issues such as high silica concentrations

- Solid chemistries to help you reduce the footprint of your treatment program

Our experienced team can also help you significantly reduce energy consumption and improve heat transfer by thoroughly cleaning the external components of your cooling coils, simultaneously improving the quality of your indoor environment.

Interested in finding sustainable solutions for your facility? Sign up to get a FREE sustainability report.

Water Management Plans for Waterborne Pathogens

ChemTreat can help develop a treatment program consistent with Cooling Technology Institute (CTI), American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), and Centers for Medicare and Medicaid Services (CMS) guidelines for reducing the risk of Legionellosis and waterborne pathogens in building water systems.

We can assist with meeting the elements of compliance through:

- Third-party Water Management Plans (WMP)

- Potable water hyperchlorination and supplemental disinfection

- Sterilizing-grade Point-of-Use (POU) filter selection

- Cooling tower cleaning and disinfection

- Automation and control

- Online real-time data logging

- Validation testing

- Education

ANSI/AAMI ST108: Standard for Water Used for Medical Device Processing

ANSI/AAMI ST108 establishes minimum requirements for water quality and steam purity for processing medical devices intended for patient use. Proper implementation of this standard improves the effectiveness and lifespan of equipment, such as ultrasonic sterilizers, endoscope reprocessors, autoclaves, and local steam generators. Implementing this standard involves a comprehensive process, starting with an assessment of current water quality management practices.

Click here to learn more about this standard, and contact us for support with ST108 testing.

Monitoring & Control with Intelligent Water Management

Our CTVista®+ intelligent water management platform enables monitoring and control of your water treatment programs by providing:

- Data management

- Analytics

- Reporting

- Real-time guidance

This cloud-based software helps our customers make real-time, data-driven decisions to:

- Protect system assets

- Minimize water, chemical, and energy costs

- Meet sustainability goals

CTVista+ combines the collective wisdom of experienced water treatment professionals with real-time data to optimize the effectiveness of the chemical treatment program at your facility.

Compatible with most industry-standard equipment setups, CTVista®+ is easy to integrate with your existing equipment. Our team can also work with you to create and install a customer equipment package best-suited to your facility’s needs.

Contact ChemTreat for Healthcare Facility Water Treatment

ChemTreat can help you improve the efficiency of your healthcare facility with best-in-class water treatment programs and products. Our experts implement treatment programs customized to the unique needs of your facility with minimal disruption to your daily business activities..

Contact us today to request a consultation with your local team member.