The Problem

A major university medical complex needed to replace more than a dozen aging cooling towers and add ten new buildings, all while transitioning to a centrally located chiller plant.

As part of this new system, the facility wanted makeup water to come from five sources, each with varying water quality properties:

- City water

- Available creek water

- Collected rainwater

- Retrieved condensate

- Reused, RO-filtered blowdown water

Facility personnel were also looking to save on costs and improve the sustainability of their water treatment program by extending the life of RO membranes and pre-filter cartridges, improving system monitoring, and reducing scale and corrosion.

The Solution

The previous process was not capable of handling a new 32,000-ton centralized plant using multiple makeup water sources.

The university partnered with ChemTreat for in-depth expertise and on-site support with this project.

After a thorough system evaluation, the ChemTreat team provided a list of recommendations and worked with the university to implement the improvements.

ChemTreat’s recommendations included:

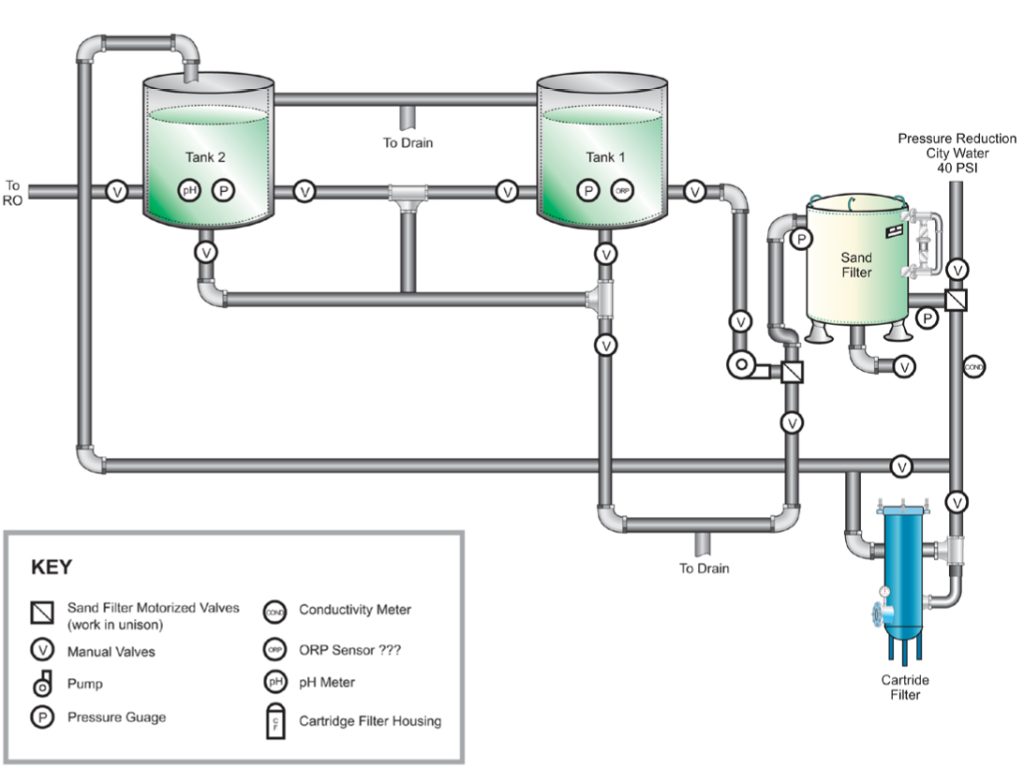

- Repositioning a sand filter in relation to the RO filtration system.

- Adding 1-micron filters to supplement the 5-micron filters for suspended solids removal (a limiting factor for RO membrane efficiency) to extend filtration run duration between cleanings.

- Implementing CTVista® intelligent water management software to solve communication issues.

- Enhancing the cooling treatment program to manage the variable water quality of five different makeup sources.

The Results

Redesigned Pretreatment Process

- Pretreatment cartridge life extended from three days to over a month.

- Off-line cleaning times reduced from five hours four times per week to just three hours every three weeks, reducing downtime, system disruptions, and costs.

CTVista Monitoring System Implementation

Thanks to the installation of CTVista, all team members with data access could write reports and other observations within a centralized system, allowing all program participants to review data and determine the appropriate course of action.

Cooling Treatment Program Enhancements

- Biocide program improvements reduced bacteria counts from 103 cfu/mL to 102 cfu/mL.

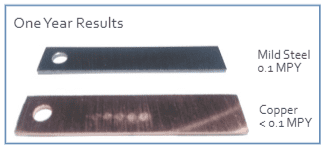

- A consistent corrosion rate of <0.1 mpy established.

- Conductivity maintained at a consistent level throughout multiple water sources.

Water Savings

With ChemTreat’s support, the university was able to save over $500,000 per year in water costs thanks to improvements to its water treatment processes.

Annual water savings from reclamation projects:

- >12 million gallons of condensate

- >20 million gallons of creek water

- >25 million gallons of recovered blowdown

Results are examples only. They are not guaranteed. Actual results may vary.