The previous installments outlined monitoring criteria to protect steam generator condensate/feedwater systems and boilers from corrosion and deposition. Steam chemistry monitoring is equally important, particularly at power plants and co-generation facilities where the steam drives turbines.

Primary Monitoring Parameters

Contaminant deposition on turbine blades can lead to corrosion and possible blade failures, which represent a potentially catastrophic situation with the turbine spinning at several thousand rpm.

Primary monitoring parameters include the following:

- Sodium: ≤2 parts-per-billion (ppb)

- Conductivity after cation exchange (CACE): ≤0.2 µS/cm

- Silica: ≤10 ppb

Sodium provides a direct indication of salt or sodium hydroxide carryover into steam. Sodium hydroxide (caustic) carryover is a particularly harmful impurity, as it can quickly induce stress corrosion cracking (SCC) of turbine components. Other salts, most notably sodium chloride, will settle in the last rows of the low-pressure (LP) turbine, where they can induce pitting and subsequent SCC and corrosion fatigue (CF) of turbine blades and rotors. Pitting is initiated during unit shutdowns, particularly if humid ambient air enters the condenser and moistens the deposits.

CACE provides a surrogate measurement of chloride and sulfate concentrations, and the ≤0.2 µS/cm limit has been a long-time guideline for turbine manufacturers. However, the accuracy of CACE is suspect, as the steam could have chloride and sulfate levels higher than typical 2 ppb limits, even while CACE stays below the 0.2 µS/cm parameter. Some instrumentation can analyze both impurities at well below 1 ppb concentration.

Silica will precipitate on turbine blades. Though the compound is not corrosive, deposits can influence turbine aerodynamics and reduce efficiency, hence the recommended limit noted above.

Common Steam Sampling Points

Several steam sampling points are common in power generating units. These include saturated, main, and reheat steam samples.

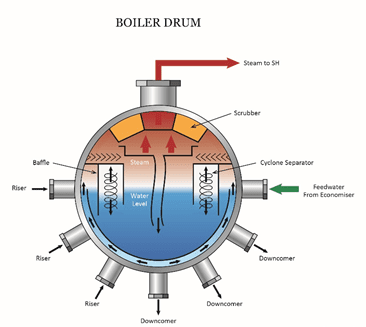

The saturated steam sample provides analyses of impurities coming directly from the boiler drum and can serve as a troubleshooting measurement to detect mechanical carryover. Mechanical carryover can be caused by damage or failure of a steam separating device in the drum.

Damage or wear of separating devices allows excessive moisture containing boiler water impurities to enter the steam.

Other factors that can influence mechanical carryover include rapid firing rates or frequent load changes that cause surges in drum water level; inadequate drum size; and boiler water contamination that may generate foam.

Special procedures are required to collect saturated steam to ensure sample integrity. This includes installing an isokinetic sampling nozzle. Major sample panel manufacturers can provide information on the proper methods to ensure integrity of all steam system samples.

Main and reheat steam analyses provide direct data on impurities entering the turbine. Of course, impurity ingress may be coming from drum mechanical carryover, but impurities can also come from contaminated steam attemperation water. Such contamination should also appear in the feedwater samples and thus be detectable at that point. Detection and correction of any mechanism that contaminates feedwater is of great importance, both to protect boiler water and eliminate direct introduction of impurities to steam.

Find the Right Treatment Options for Your Facility

To learn more and request a consultation of your steam generation systems, contact ChemTreat. Our experienced team can help you design a monitoring and treatment programs suited to your plant’s unique needs.

Of course, all systems are different, and due diligence is necessary to determine the feasibility of utilizing methods. Always consult your equipment manuals and guides and seek guidance from a water treatment professional.