This blog series focuses on different aspects of steam generator chemistry monitoring. Part 1 discussed high-pressure system monitoring recommendations, and Part 2 examined the condensate system.

This discussion on feedwater sampling in steam generator water and steam chemistry monitoring is closely related to the previous installment, especially regarding the recommended instrumentation. The circuit in high-pressure steam generators, and particularly power producing units, is nearly closed (or should be), with only moderate makeup addition. If the condensate chemistry outlined in Part 2 is in order, the feedwater chemistry should also be satisfactory. However, the feedwater sample (ideally at the economizer inlet [EI] or even better, the economizer outlet) is critical, as it typically represents the primary location for evaluating flow-accelerated corrosion (FAC) in the feedwater system. Furthermore, condensate/feedwater treatment chemicals are added after the condensate pump discharge (CPD), so the feedwater sample is the prime location for monitoring chemical dosages and their effects.

For standard systems, recommended continuous feedwater analyses are:

- Cation conductivity (CACE): ≤0.2 µS/cm

- Specific conductivity (SC): Consistent with pH

- Sodium: ≤2 ppb

- Dissolved oxygen (DO): 5–10 ppb

- pH: 9.6–10.0 (This is the pH range for the most common HRSG design, the triple-pressure, feed-forward low-pressure type. The range may be a bit different for other HRSG designs.)

- Total iron: ≤2 ppb

The sodium and CACE samples often serve as excellent backups for the same instrumentation at the CPD. Detection and response to contaminant ingress is typically the highest priority in high-pressure units, and redundant readings from the feedwater instruments can be quite beneficial in confirming whether an upset is real or the result of a faulty analyzer. Although rare, at times impurities have been known to enter the steam generator through contaminated feedwater treatment chemicals, which these instruments would typically detect. Finally, in most high-pressure units, a small slipstream of feedwater is utilized for steam attemperation. This arrangement can introduce impurities directly to the superheater/reheater and turbine. Sodium hydroxide, chloride, and sulfate in particular can be very damaging to these components.

As mentioned in Part 2, ammonia (or sometimes an amine or ammonia/amine blend) is the normal pH-conditioning agent for condensate/feedwater. However, direct pH measurement of high-purity water can be tricky, and algorithms have been developed to calculate pH based on SC and CACE measurements to provide more accurate results. SC in high-purity water is directly correlated to the ammonia concentration, so SC measurements offer better control of ammonia/amine feed than pH.

Virtually no modern steam generators, especially HRSGs, have copper alloys in the feedwater system. Thus, oxygen scavengers/reducing agents are not recommended for these units, but a small amount of DO (5–10 ppb) is necessary to establish the most protective iron oxide layer on carbon steel piping. To do so may require closing deaerator vents (for those systems so equipped), but not without proper upfront evaluation.

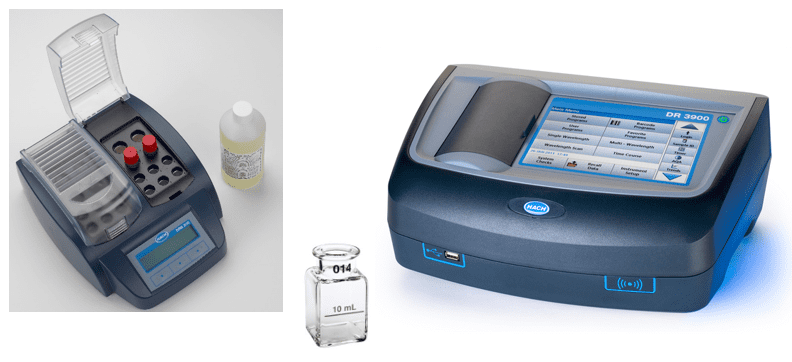

In recent years, iron monitoring has become a very important function in many systems. It provides direct indication of FAC and how effective the chemistry program is in mitigating this corrosion mechanism. Most iron in condensate and feedwater exists in particulate form, so analytical methods for only dissolved iron grossly underestimate the total concentration. Corrosion product sampling is a method that filters a sample over time, after which the concentration is determined by digestion of the filter, with subsequent dissolved iron analysis. Hach offers an inexpensive grab sample method, which includes a digestion step, for iron monitoring. Analyses can be performed daily, weekly, or at any frequency desired by plant personnel, and on any of several important streams including condensate, feedwater, and boiler water.

Figure 1. Combination reagent, digestion vials, and heater block (left); 1-inch sample cell (center), and spectrophotometer (right). Photos courtesy of Hach.

ChemTreat can help you address challenges around steam generator chemistry monitoring. Contact us for assistance in designing a monitoring program customized for your application.

Like all other technologies, due diligence is necessary to determine the feasibility for utilizing methods. Always consult your equipment manuals and guides and seek ChemTreat guidance to address your specific system needs.