A large East Coast brewery struggled with rusting around the skirts of their bottle caps. The brewery was using a zinc/phosphate treatment program, but it did not provide sufficient corrosion protection. The primary cause of the rusting was metal-to-metal contact at the crowner, but the customer wanted an intermediary chemical solution to better protect the crowns until the mechanical issue could be addressed.

ChemTreat’s R&D team performed a pilot study to recreate the pasteurizer conditions and reproduce the corrosion issue.

Pilot Study Results

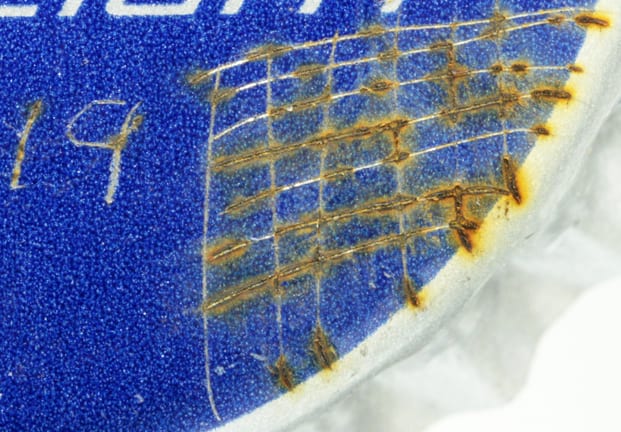

No treatment:

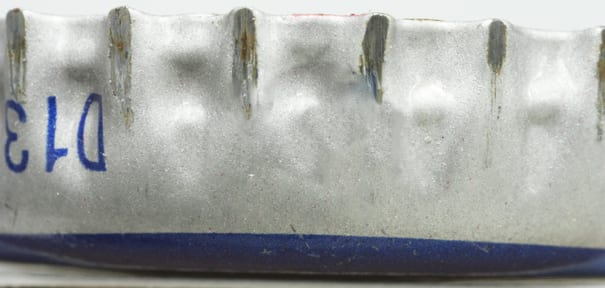

FlexPro® Treatment:

After seeing the dramatic decrease in corrosion from the pilot study, the brewery agreed to run a field trial.

The field test results were a success. ChemTreat’s treatment outperformed the incumbent water treatment supplier’s program, dramatically reducing bottle cap corrosion without using phosphate or zinc.

Bottle Cap from Pasteurizer Treated with Zinc/Phosphate Treatment Program:

Bottle Cap from Pasteurizer Treated with FlexPro®:

Results are examples only. They are not guaranteed. Actual results may vary.