The Problem

A hydrocarbon company with operations in the Eastern Plains and southern Colombia chemically treats its wastewater effluent before discharging into a local river to comply with environmental regulations.

Water treatment consists of a clarification method to generate flocs that can be decanted into oxidation pools. As the oxidation pools become saturated with the decanted flocs, wet sludge recovery is performed in a decanter followed by a drying riverbed.

The plant was struggling with the following challenges in their wastewater treatment process:

- The size of the decanter and drying riverbed were insufficient to treat the volume of waste generated.

- Very limited residence time prevented at least 30% of the water from being removed in the drying riverbeds, causing increased transportation costs as more trucks were needed to remove the wet sludge from the field.

The Solution

To help the customer improve their sludge dewatering process, Lipesa (part of the ChemTreat family of companies) conducted a complete audit process and proposed a customized effluent treatment solution:

- Use of LIPESA 1564 to dehydrate and compact the sludge

- Development of a specific protocol to take advantage of existing equipment and avoid additional investments and costs.

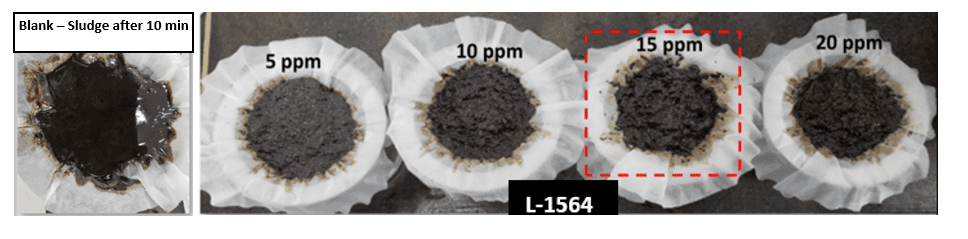

Product Dosage Selection

The Results

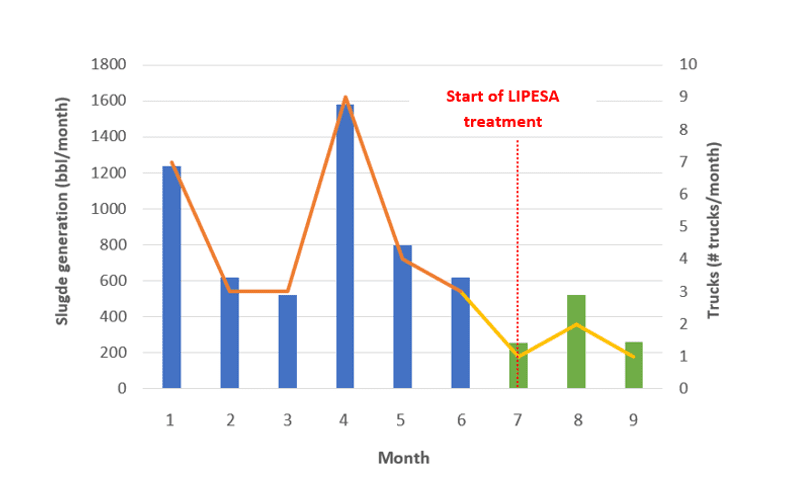

Thanks to the implementation of the Lipesa treatment program, the facility saw the following improvements:

- 57% decrease in the volume of waste generated (barrels per month)

- 77% increase in efficiency of the dehydration of sludge recovered from oxidation pools

- 10,000 USD per month saved thanks to the reduction in vacuum trucks needed to remove the dry sludge

Field Implementation: Sludge Volume Reduction

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.