The Problem

A hospital in Virginia was using a traditional liquid cooling treatment program to manage corrosion, deposition, and fouling in their system. However, the presence of large containers of corrosive chemical on-site was causing storage and handling concerns.

The Solution

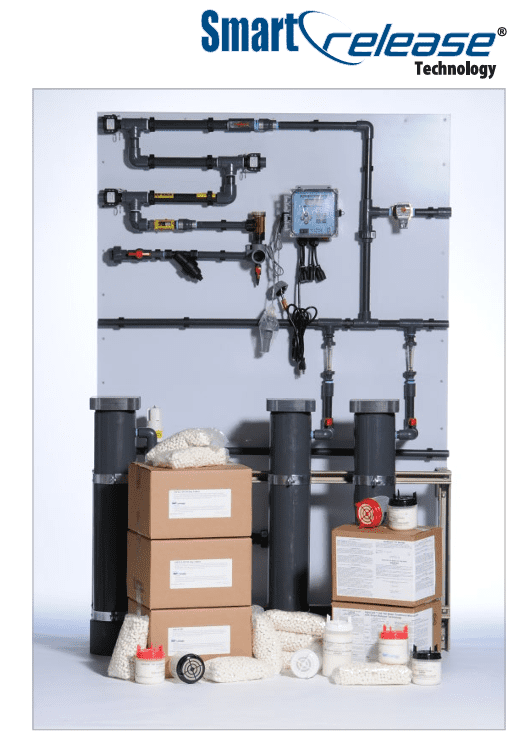

Based on recommendations from ChemTreat, hospital personnel decided to switch to Smart Release® solid cooling treatment technology to reduce chemical handling and storage requirements while maintaining system corrosion, scale, and fouling at appropriate levels to preserve assets and system efficiency.

The Results

The Smart Release inhibitor treatment system was installed with canister feeders to apply the solid products, replacing the liquid cooling corrosion inhibitors and oxidizing and nonoxidizing biocides.

Switching to Smart Release® provided the following benefits to the hospital:

- The patented polymer coating on Smart Release tables controls the release of chemical, so product is fed only when the cooling tower is running and the feeder has flow. When flow stops, the osmotic pressure gradually equalizes to pause chemical feed. This enables treatment to be applied without using electrical pumps, saving on energy use.

- Transportation fuel consumption was reduced, as over 650 pounds of liquid cooling treatment were replaced with 100 pounds of Smart Release chemical.

- With 100% recyclable packaging and feeders made of recycled materials, the Smart Release program helped the hospital achieve environmental goals. Smart Release even improved the facility’s LEED rating.

- The consistency of product feed reduced the frequency of testing, freeing up personnel for other projects.

Based on the success of this program, hospital personnel decided to convert five other sites to Smart Release.

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.