The Problem

Process leaks in a fractionation plant’s cooling water system were leading to increased microbiological growth, necessitating increased amounts of bleach feed to maintain control. The fill in one tower was so plugged up with biological fouling that water and air flow were significantly impacted.

The quality of the makeup water used in the cooling towers presented an additional treatment challenge. The water contained hydrocarbons and microbes, and the ORP could reach as low as -200 mV, making it more difficult to treat effectively.

The Solution

Seeking to improve bleach performance and reduce the microbiological fouling occurring in the system, the facility began a trial of ChemTreat’s patented SurfClean 2.0, an innovative solution designed to address microbial fouling issues.

The local ChemTreat team set up a pump with a timer to slug feed SurfClean 2.0 twice per day. The team used a Teflon™ tee to mix bleach and SurfClean 2.0 at the optimum ratio and pumped the mixture into the tower basin through a short 10-foot tubing run.

The facility was able to eliminate the feed of separate antifoam and surfactant treatments, as both are contained within the SurfClean 2.0 formula.

The Results

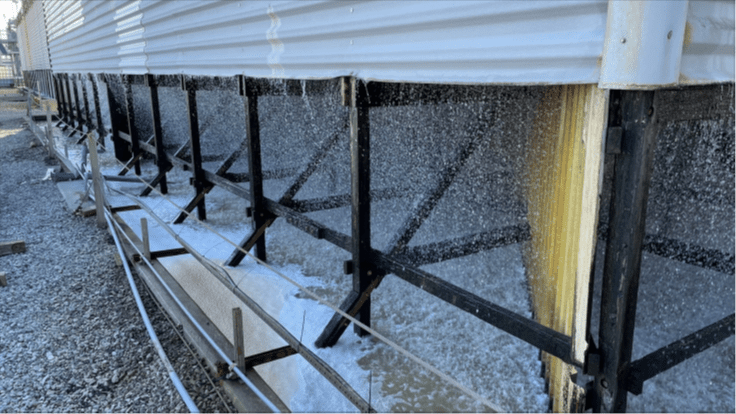

At the start of the SurfClean 2.0 treatment program, the tower screens required daily cleaning to remove biofouling released from the tower surfaces, which had accumulated during the previous treatment program.

At the beginning of the trial, SurfClean 2.0 flushed out biofouling accumulated during the previous treatment program.

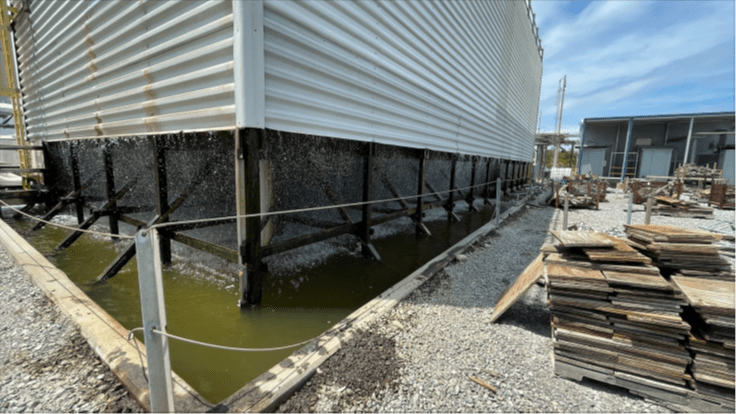

After three months of using SurfClean 2.0, the air flow in the cooling towers increased, the water flow through the tower fill was more uniform, and biological growth in the fill was significantly reduced.

While the cooling water routinely contains 0 ppm of free chlorine because of process leaks, the total residuals are robust, with over 1.3 ppm of total chlorine being a typical reading. Dip slides used to monitor microbiological fouling showed no growth (<102 cfu/mL).

The poor makeup water quality in this system presented significant treatment challenges, but the application of SurfClean 2.0 resulted in improved water flow through the tower and reduced microbiological populations in the system while cleaning the tower fill.

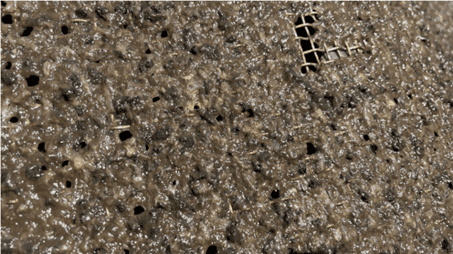

Back corner of the cooling tower basin before the trial.

Back corner of the cooling tower basin two months into the trial. The water fall and wind circulation improved after SurfClean 2.0 application, indicating cleaning of the cooling tower fill.

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.