FlexCorr™ for Advanced Corrosion Control

ChemTreat’s technical and R&D teams are committed to developing technologies that solve your most challenging water treatment issues.

In the spirit of continuous improvement, we have developed an advanced suite of low-phosphorus/low-zinc cooling treatment programs that provide all the benefits of our trusted FlexPro® technology while helping facilities protect their assets with a synergistic combination of strong anodic and cathodic corrosion inhibitors.

FlexCorr is especially effective for cooling systems that use corrosive waters with a wide range of pH and alkalinity.

Non-phosphate, non-zinc product options are also available for facilities looking to improve their environmental impact

Benefits of FlexCorr over industry-standard programs include:

Case Study: Improving Corrosion Control and Reducing Operational Costs with FlexCorr

ChemTreat’s FlexCorr cooling treatment products help facilities improve cooling system efficiency while meeting environmental goals.

A large refinery on the Gulf Coast was feeding non-phosphorus corrosion inhibitors to protect their heat exchangers from corrosion. Looking to improve cost performance while maintaining corrosion rates and complying with environmental discharge permits, they decided to switch to ChemTreat’s FlexCorr corrosion inhibitor treatment.

Read the case study to learn more.

How FlexCorr Works

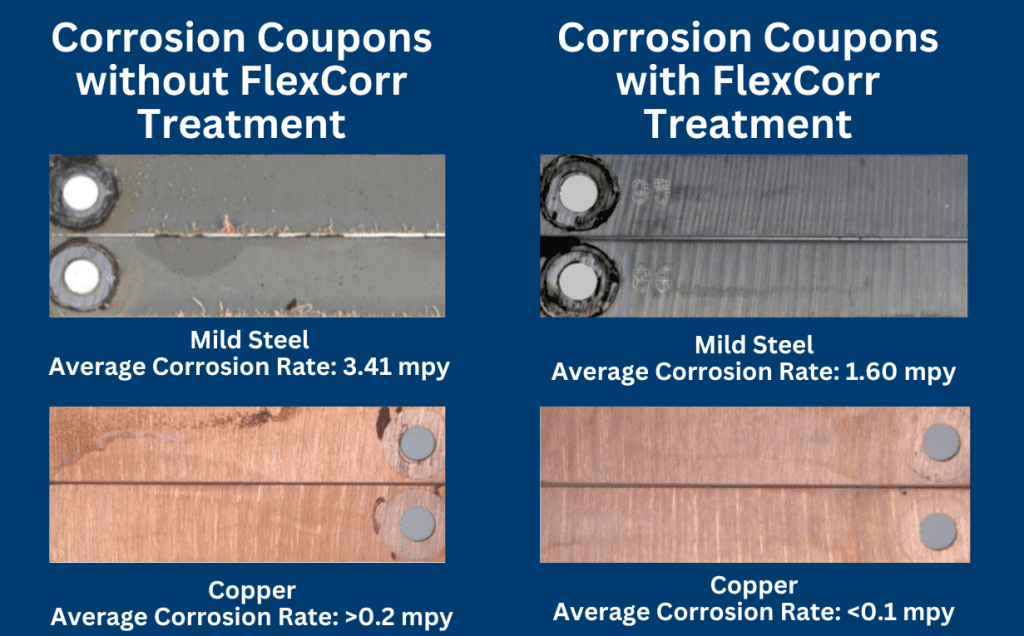

FlexCorr offers best-in-class corrosion performance and will not cause system scaling or fouling under typical operating conditions, reducing the need for frequent cleanings and associated downtime and costs.

This technology has shown great results in reducing corrosion in heat exchanger systems using mild steel and copper metallurgy. Effective corrosion inhibition helps facilities improve the life of their assets and increase production efficiency by reducing plant downtime.

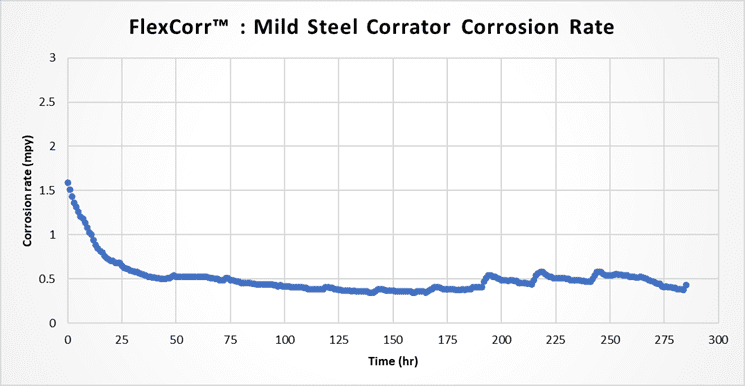

Data from the pilot cooling tower showing the reduction in corrosion rates on mild steel metallurgy after FlexCorr application