The Problem

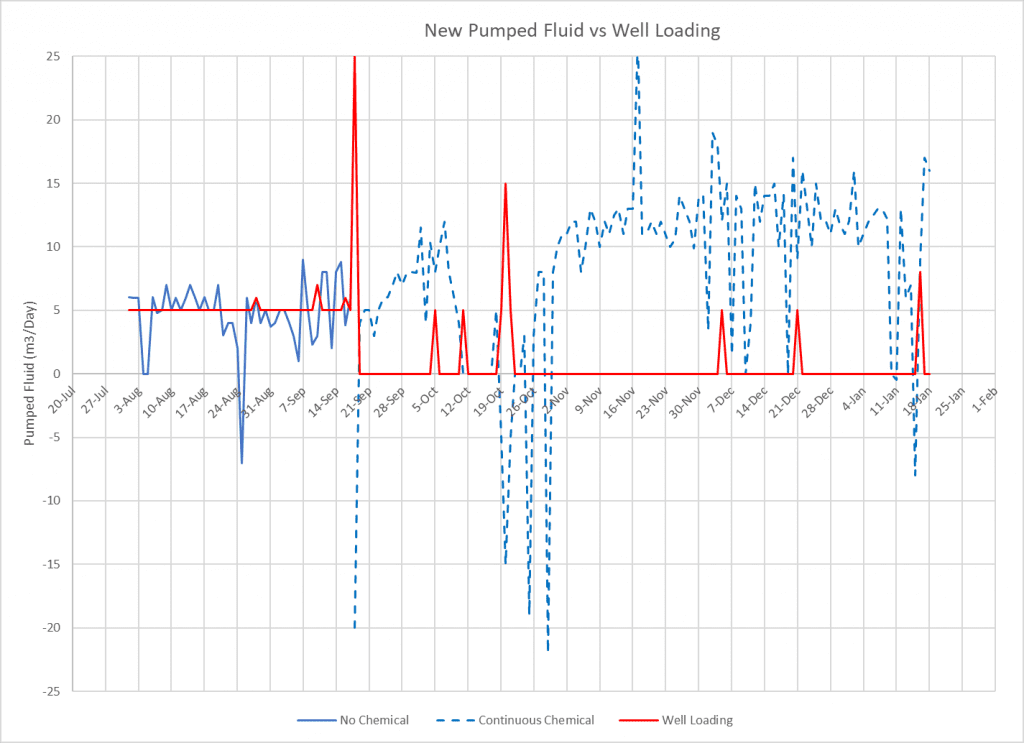

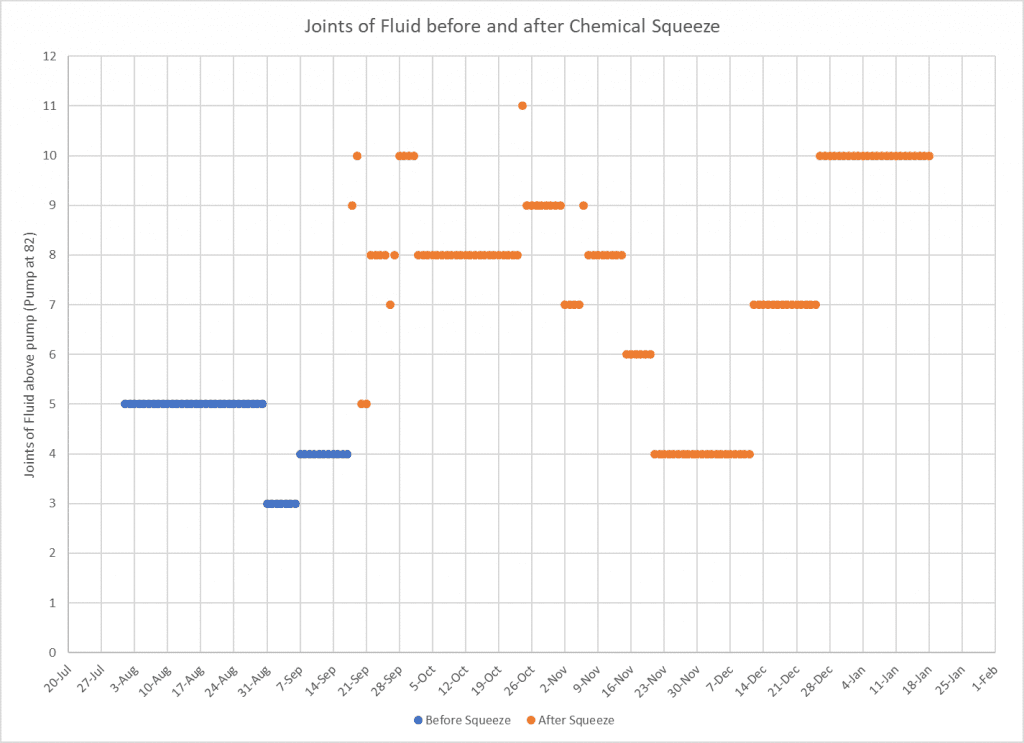

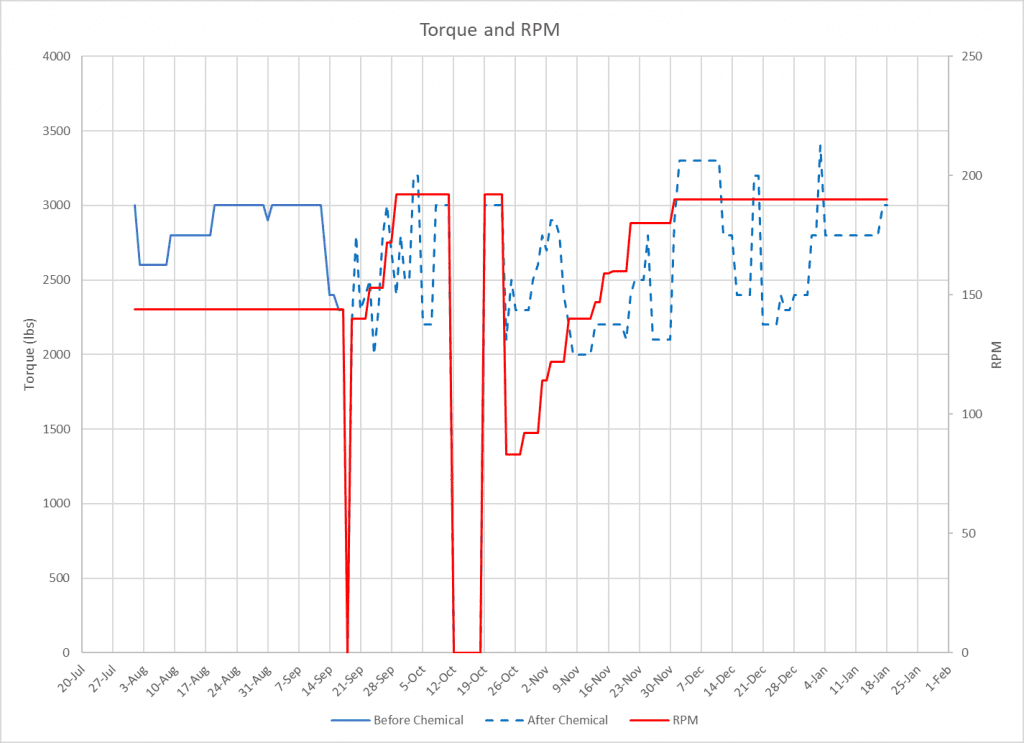

A Cold Heavy Oil Producing Sand (CHOPS) producer in Northern Alberta, Canada had a high-torque (approximately 3,000 pounds) low-inflow well. This was a vertical well completed into the Cummings and McMurray Zone, and the Progressing Cavity Pump (PCP) was placed at 82 joints with fluid level at 79 prior to treatment. Field operations were loading the well with 5 m3 of hot oil daily to temporarily reduce torque, producing roughly 2.1 m3 of oil per day.

The Solution

ChemTreat recommended a chemical squeeze with a 24-hour soak to clean out the near wellbore fouling and continuous backside chemical injection to reduce torque.

The Results

Well inflow dramatically improved after the squeeze and fluid level increased to 72 joints. The torque was initially reduced to approximately 2,200 pounds, allowing field operations to increase the speed of the PCP and stop daily well loading. ChemTreat’s chemical program and asphaltene control product helped the customer increase oil production from this well to approximately 8.6 m3 per day.

The annual benefit to the customer from increased production and reduced well loading was calculated to be approximately $442,906 from this chemical application.

Results are examples only. They are not guaranteed. Actual results may vary.