The Problem

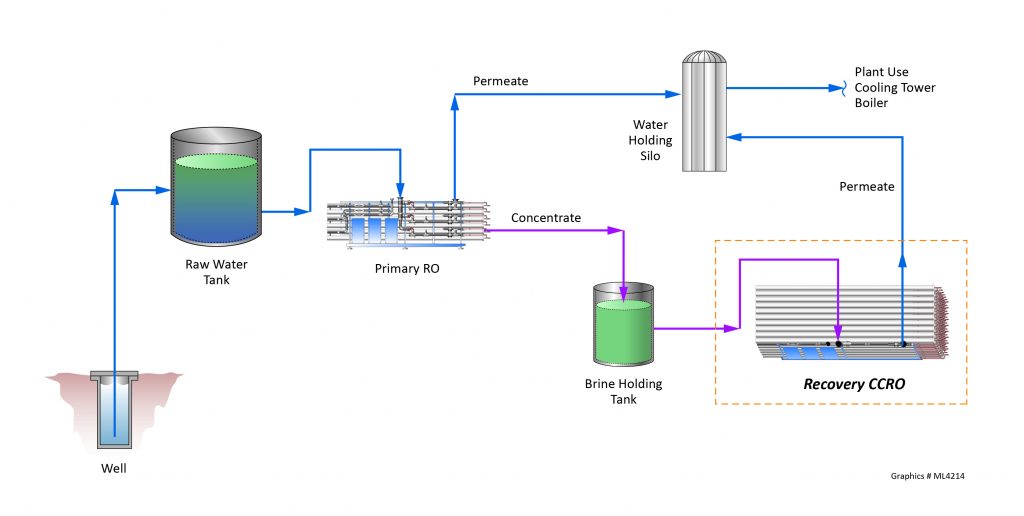

A winery installed a reverse osmosis (RO) system to produce clean permeate water for bottle rinsing, cooling, and boiler water makeup. Three conventional ROs and one reject recovery closed-circuit RO (CCRO) with total recovery rate of around 87.5% were designed to treat a well water source with high alkalinity and silica concentrations over 50 ppm.

During system startup, the feed pressure at the CCRO increased within a matter of hours, forcing system shutdown for a membrane clean-in-place (CIP) with a high-pH cleaner to restore membrane system performance. Typically, systems using well water require CIPs approximately 2–3 times per year, but the feed pressure increases forced recovery RO shutdown for CIPs every few days, impacting overall system water efficiency and operational expenses.

Reverse osmosis setup at the winery facility. The recovery CCRO was experiencing high feed pressures, requiring frequent CIPs.

The Solution

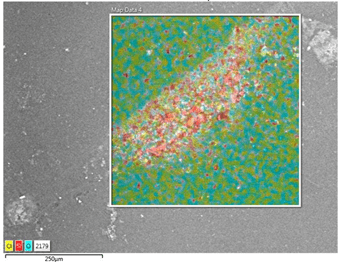

ChemTreat performed a membrane autopsy and discovered that silica from the well water was scaling the system and causing the rapid increase in CCRO feed pressure.

Membrane autopsy image showing silica scale buildup

A revised chemical treatment program included CCRO pH adjustment from 7.8 to 6.7–6.8 and application of RL9909, a high-stress traced scale inhibitor, to slow down silicate kinetics and scale-forming polymerization.

Other improvements included increasing permeate flush time at the primary ROs to improve dilution in the brine tank on the weekends when the systems are idle for longer periods. The brine tank was cleaned to remove algal slime buildup on the inside walls, and the outside tank walls were painted black to help prevent further slime growth.

Additionally, ChemTreat audited the CIP process and made several recommendations for improvements. High-pH membrane cleanings have been implemented, and a tank heater issue was fixed to allow the CIP cleaning solution to be maintained at the desired temperature for optimal cleaning.

The ChemTreat team also assisted the customer in developing an in-house monitoring and normalization program to track RO performance to aid with RO analysis and maintenance.

The Results

After ChemTreat’s recommendations were implemented, the CCRO feed pressure rate increase was reduced, and the winery was able to increase time between CIPs from once every couple of days to 3–4 times per year, freeing up employees to do higher value work.

Total system efficiency was improved from 75% recovery without the CCRO to 86% overall system recovery, meeting the plant’s goals and providing return on investment for their capital expenditures for reverse osmosis equipment.

Results are examples only. They are not guaranteed. Actual results may vary.