The Problem

A hospital system had a very serious problem with staining and corrosion on reusable medical instruments caused by the cleaning and sterilization process. This particularly affected specialized knives. The problem was so severe that surgeries were interrupted, postponed, and even canceled until properly prepared instruments could be made available to the surgeons.

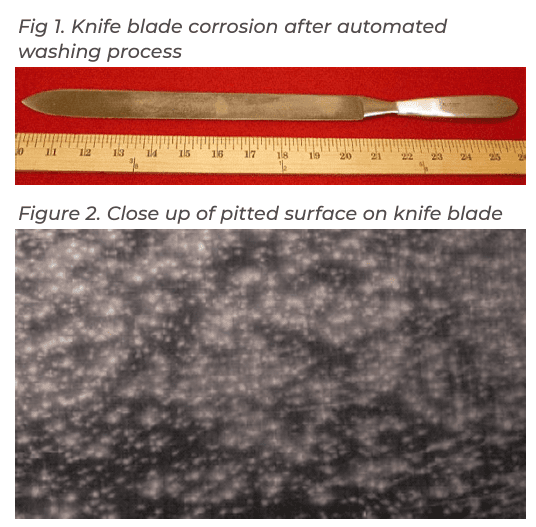

Figure 1 shows a corroded amputation knife after going through the automated washing process prior to sterilization. Since the knife blade was corroding but not the handle, it was determined the chromium content of the blade was not sufficiently resistant to corrosion. In addition to pitting corrosion, the surface was found to have clusters of mineral deposits.

The first three of the four automated washing stages used unsoftened tap water. The final rinse stage used demineralized water, but only rinsed for ten seconds.

The Solution

Based on ChemTreat’s recommendations, the facility instituted the following changes in the wash cycle:

- More attention paid to the pre-wash steps.

- Purified water incorporated earlier in the washing procedure.

- Water source quality maintained at appropriate levels to reduce corrosion.

ChemTreat also recommended switching to blades made with a more corrosion-resistant alloy.

Thanks to these improvements, the facility was able to solve their issues with medical instrument corrosion while improving the sterilization process overall.

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.