The Problem

In order to ensure product quality, a brewery in western Mexico had to stop its production line for one hour every day for cleaning. To achieve the required cleanliness, the brewery had to manually add foam filler, rinse, and perform additional mechanical cleanings. This cleaning involved 4–5 line personnel for at least 1 hour per day and required the line to stop production for the entire cleaning period.

Considering that the facility packages beer at a speed of 550 bottles per minute, the brewery was losing critical production time because of this cleaning process.

The Solution

The facility began applying ChemTreat’s FillerScrub™ technology for on-line cleanings to reduce the off-line cleaning time. The on-line cleaning system is designed to maintain production line cleanliness between off-line cleanings, thereby reducing production downtime.

The Results

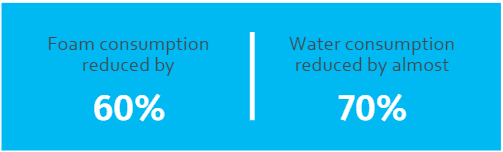

FillerScrub™ reduced off-line cleaning time from 1 hour to 20 minutes per day. Personnel required for the cleanings decreased from 4–5 down to just 2. Foam consumption was reduced by 60%, and water consumption was reduced by almost 70%. The reduction in off-line cleanings increased production time by 10,000 minutes per year, allowing for more effective use of line personnel to produce additional product.

Results are examples only. They are not guaranteed. Actual results may vary.

Click here to read another case study on ChemTreat’s filler cleaner technology.