Fundamentals of Pharmaceutical Water Treatment

Pharmaceutical plants typically contain numerous batch reactors, distillation columns, crystallizers, and additional heat exchangers, which require both open evaporative and closed cooling water systems, making well-maintained cooling tower chemistry essential to plant reliability and efficiency.

The diagram below illustrates the problematic issues that can plague cooling systems, and how each issue can influence the others.

Watch the full webinar online.

Another fundamental aspect of these systems is cooling tower discharge. For nearly four decades, the most common corrosion/scale control program for industrial cooling towers relied on a core chemistry of inorganic and organic phosphate compounds. This chemistry establishes mildly alkaline conditions in cooling water to reduce the potential for general corrosion, and it relies on controlled deposition of phosphate compounds, including calcium and iron phosphate, for additional corrosion control. A small concentration of zinc is often included for additional corrosion control, with the organic phosphate (aka, phosphonate) portion and a supplemental polymer providing scale inhibition.

ChemTreat Develops FlexPro® Technology

However, there is an increasing concern over the impact of phosphorus on the environment, particularly the growing issue of toxic algae blooms in natural bodies of water. In many locations, industrial discharge containing phosphorus is being regulated.

To mitigate this issue, ChemTreat developed our proprietary, sustainable, and non-fouling FlexPro® technology. The majority of FlexPro products do not contain phosphate. This non-phosphorus formulation interacts directly with the metal surfaces to form a protective layer, which, unlike phosphate/phosphonate programs, does not rely on deposition of reaction products to form this barrier.

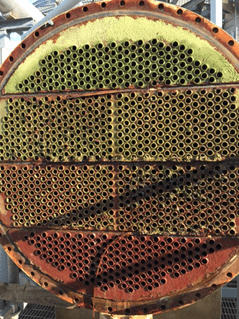

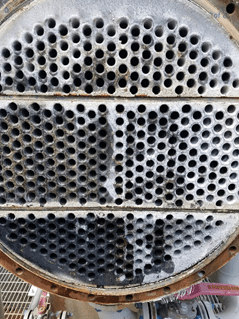

Full-scale application of this chemistry has proven very effective. At one chemical plant, the two-pass heat exchanger was suffering from corrosion on the low-temperature inlet side and calcium phosphate deposition on the high-temperature outlet side from reverse solubility of phosphates at higher temperatures. FlexPro helped the customer solve both problems.

Before FlexPro Treatment

After FlexPro Treatment

For pharmaceutical plants that produce a variety of products and may have numerous cooling systems of different sizes and complex metallurgies, FlexPro may be a great treatment option. Easier to control than traditional phosphate/phosphonate chemistries, this innovative technology helps facilities reduce phosphate discharge to meet their environmental goals while maintaining superior corrosion performance without fouling concerns.

Like all other technologies, due diligence is necessary to determine the feasibility for utilizing this technology. Always consult your equipment manuals and guides, and contact ChemTreat for help designing a water treatment program customized to your specific needs.