The Problem

An automotive parts manufacturer was experiencing problems with dirty parts leading to paint defects. Many parts had to be rerun, which resulted in higher water usage rates. The final rinse stage was also leaving water spots, so extra labor was required to wipe down parts prior to painting.

The Solution

ChemTreat performed a complete system audit and developed a custom solution for the customer’s issues.

The parts washer chemistry and the feed equipment were upgraded, and the feed points were changed. The system stage overflow was changed to reduce water consumption, and air blowoff was optimized to improve product quality.

Regular service visits were scheduled to monitor and document system improvement.

The Results

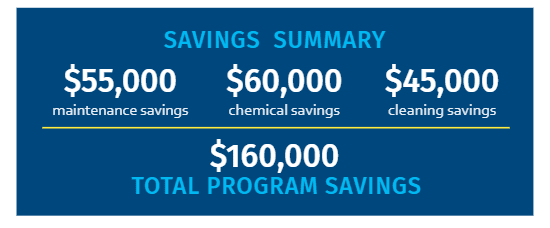

Thanks to the ChemTreat program, the customer experienced the following results:

- Eliminated water spotting on parts

- Decreased reject rate by 12%

- Reduced chemical usage by 30%

- Reduced reverse osmosis usage by >500,000 gallons per year

- Reduced city water usage by >480,000 gallons per year

- Reduced system cleaning frequency

- Reduced disposal and maintenance requirements

Contact us to learn more and schedule a consultation.

Results are examples only. They are not guaranteed. Actual results may vary.