Pharmaceutical companies (as well as semi-conductor manufacturers and high-pressure steam generating power stations) require high-purity makeup water for their processes. Impurity concentrations have to be in the very low parts-per-billion (ppb) range or even lower. Reliable and efficient production of high-purity water is integral to these efforts.

In the last century, the development of synthetic ion exchange resins was a major steppingstone for high-purity water production. Resins to remove dissolved cations such as calcium, magnesium, sodium, etc. and anions, chloride, sulfate, and even weakly ionized silica became a workhorse for treatment systems. However, it became apparent that, when utilized as the primary purifying technique for makeup water, ion exchange resins can quickly become exhausted because of the substantial concentration of ions in the makeup supply, even from fresh water sources. These systems often required daily regenerations of exchange resins with strong acid for cation resins and caustic for anion resins.

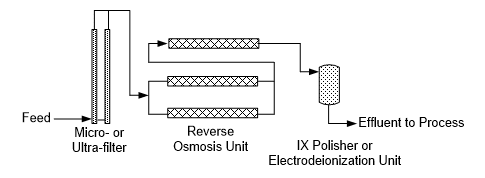

The development of membrane technologies significantly altered this process. A common core configuration for high-purity makeup water preparation in modern industry is outlined below.

Modern reverse osmosis (RO) membranes can remove over 99% of dissolved solids, which requires polishing the RO permeate by ion exchange or electrodeionization (EDI), or sometimes both in series, to produce high-purity makeup.

Pretreatment is a critical aspect of reliable RO unit operation, particularly minimizing fine particulate carryover to RO membranes. Many 20th-century water treatment systems were designed with clarifiers, followed by multi-media filters, to remove most of the suspended solids from the incoming plant makeup stream. Like other technologies, clarification has been greatly improved over time, and modern clarifiers may now operate at 10–20 times greater rise rates than the conventional large, circular clarifiers of the past. However, fine particulates can still escape with the clarifier/filter effluent and foul RO membranes, especially the leading elements. Microfiltration (MF) or ultrafiltration (UF) is often recommended for new makeup water systems to provide low suspended solids RO feed. MF or UF may be placed downstream of a clarifier or may sometimes serve as stand-alone filtration devices.

Unlike RO elements, which utilize spiral-wound membranes (as will be shown in Part 2 of this series), microfilter and ultrafilter membranes typically have the hollow-fiber configuration, in which the membranes resemble long spaghetti strands or fibers, typically called lumens. Pressure-type systems are common.

In this type of MF unit, the fibers are housed within pressure vessels connected in parallel.

The unit shown in Figure 2 was chosen as a replacement for an aging clarifier, whose primary function was to remove suspended solids from a lake water supply. Results from the changeover were immediate, and in some cases readily observable. For example, the turbidity of the inlet stream to the RO unit dropped from a typical range of 0.5–1.0 NTU (nephelometric turbidity units) to less than 0.05 NTU. The time between RO cartridge filter changeouts increased from weeks to months. In addition, upstream MF or UF improves RO performance, typically reduces the frequency of membrane cleanings, and extends membrane life.

Ultrafiltration is very common today, offering even finer filtration than MF. Table 1 outlines general pore sizes for the four major membrane technologies.

Table 1 – General Membrane Pore Sizes

| Rule of Thumb Membrane Pore Sizes |

| Microfiltration – 0.1 µm |

| Ultrafiltration – 0.01 µm |

| Nanofiltration – 0.001 µm |

| Reverse osmosis – 0.0001 µm |

An important point to remember is that MF and UF are designed solely for particulate removal, while nanofiltration and RO remove dissolved ions. The functions cannot be interchanged.

ChemTreat has experience helping customers with their high-purity makeup water treatment challenges. Look for future posts on this topic and contact us for assistance in designing a treatment program customized for your application.

Like all other technologies, due diligence is necessary to determine the feasibility for utilizing methods. Always consult your equipment manuals and guides.