The Problem

Flare gas recovery units (FGRUs) are used in refineries to limit the amount of waste gas sent to the flare, enabling facilities to treat and recover high-value fuel gas. The re-pressurization of flare gas ensures the majority of the gases are recycled to the sour fuel gas system within the plant instead of to the surrounding environment. This gas/liquid mixture circulating within the FGRU poses a unique challenge for water treatment, as corrosion rates are very high because of the presence of acidic gases.

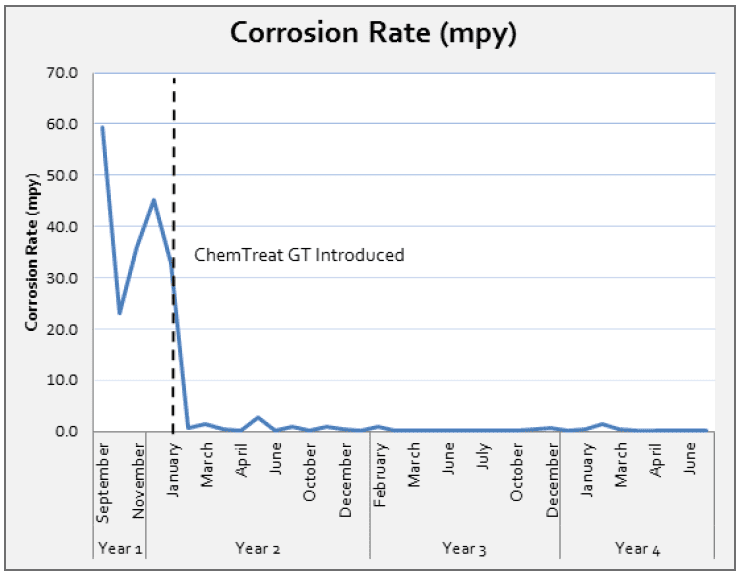

A large Midwestern oil refinery was plagued with FGRU corrosion. In the service liquid loop, fin fan coolers and lines experienced corrosion rates as high as 59 mpy. In addition, high turbidity levels in the sour water blowdown caused deposition, contributing to equipment downtime.

The Solution

ChemTreat recommended its Gas Treatment (GT) product line specifically designed for use in refineries and sour gas industries to reduce corrosion in the refinery’s FGRU.

The Results

After the introduction of ChemTreat GT, FGRU corrosion decreased to an average of 0.45 mpy. Additionally, water clarity in the sour water blowdown significantly improved, reducing deposition in the FGRU. This treatment helped the facility reduce energy waste and meet their environmental goals.

Corrosion data before and after the introduction of ChemTreat GT

Download the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.