The Problem

A large beverage manufacturing facility in the Southwestern US uses significant amounts of water to produce hundreds of thousands of cases of product every year. Facility personnel were looking for a way to reuse water at the plant to achieve cost savings and meet environmental goals.

The aseptic production line at this plant uses an antimicrobial agent to sterilize bottles. The bottles are then rinsed with sterile reverse osmosis (RO) water heated up to pasteurizing temperatures and cooled down. This water was being sent to drain at the rinser, resulting in high water costs. The ChemTreat team was asked to come up with a way to reuse this water in other processes instead.

The Solution

The sterile water leaving the rinser has a low conductivity (<500 µS/cm), which made it a good candidate for reuse, but it is also low in pH. To counteract low-pH corrosivity, ChemTreat implemented our UC3002 treatment product, a synergistic blend of alkalinity boosters and scale inhibitor to reach a setpoint pH of 6.5–8.2.

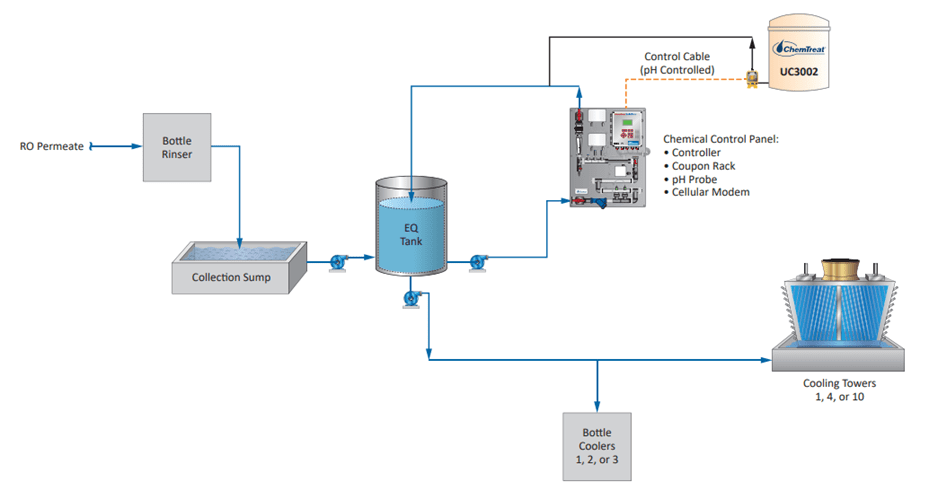

Process flow of reclaim water

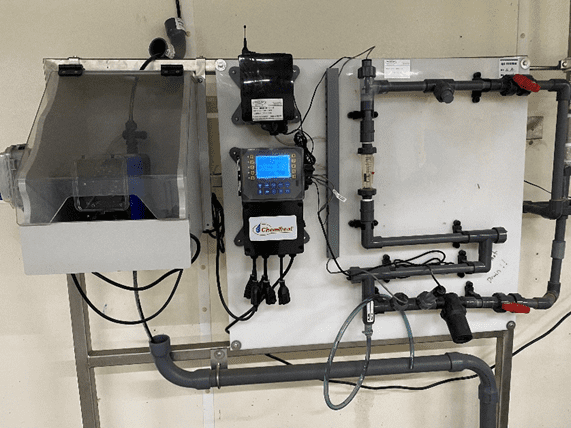

To maintain a constant pH, the site installed a control panel consisting of an Advantage Controls MegaTron controller, flow switch, pH probe, cellular data modem, corrosion coupon rack, and chemical dosing pump.

- MegaTron controller: Receives information and data from the pH probe and sends a signal to the chemical pump and modem.

- Flow switch: Ensures chemical is not fed to the system when no flow is detected.

- pH probe: Actively measures pH in the water stream and transmits data to the controller.

- Cellular data modem: Allows for remote communication with the controller so pH can be monitored anytime and anywhere. It also provides alarm emails and messages so system problems can be addressed quickly.

- Corrosion coupon rack: Helps personnel monitor corrosion rates and make adjustments as needed.

- Chemical dosing pump and box: Receives controller signals to determine when chemical needs to be added. The pump is enclosed in a box as a safety measure in case pump failure results in uncontrolled release of chemical.

Control panel with associated equipment

Overview of system, including control panel, mixing tank, and chemical tote

After treating the sterile RO water with UC3002, the water quality was suitable for use in various applications, including cooling towers and bottle coolers. The water is sent to different systems as determined by the controller.

The Results

Implementing this reuse program saves an average of 35 gpm of water when the rinser is running. An estimated 20–30% of RO water from the rinser has been reused in the first year of implementation, saving between 1.17 and 1.76 million gallons of water.

The plant plans to connect this reclaim system to other water systems in the future to enhance water savings and reduce costs at the facility.

Dowload the Case StudyResults are examples only. They are not guaranteed. Actual results may vary.