The Problem

A data center in the Midwest runs two 650-ton chillers as part of their cooling system. They were already feeding solid cooling treatment chemical for scale and corrosion control but lacked monitoring and inventory management capabilities. This resulted in the underfeed of bromicide, causing poor bacteria, slime, and algae control in the cooling towers.

The Solution

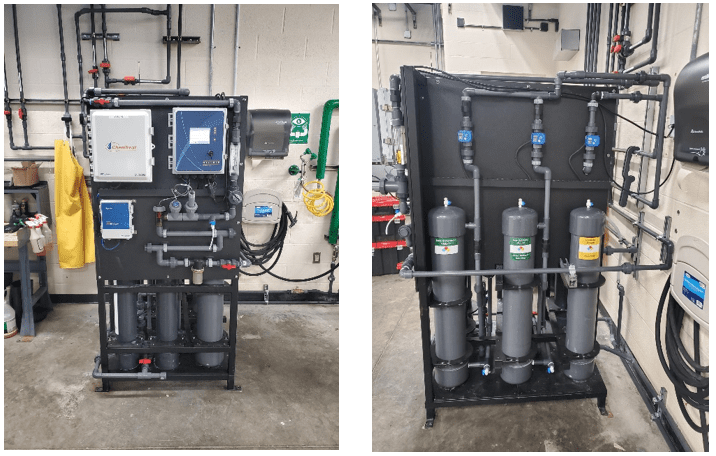

ChemTreat worked with our partner Dober to install SRG2, the second generation of Smart Release solid cooling treatment feed system at the customer site. A control and monitoring program was set up to track key performance indicators such as conductivity, PTSA, and ORP.

The second-generation Smart Release setup at the customer site. Solid cooling treatment takes up significantly less space than standard liquid cooling treatment programs.

The Results

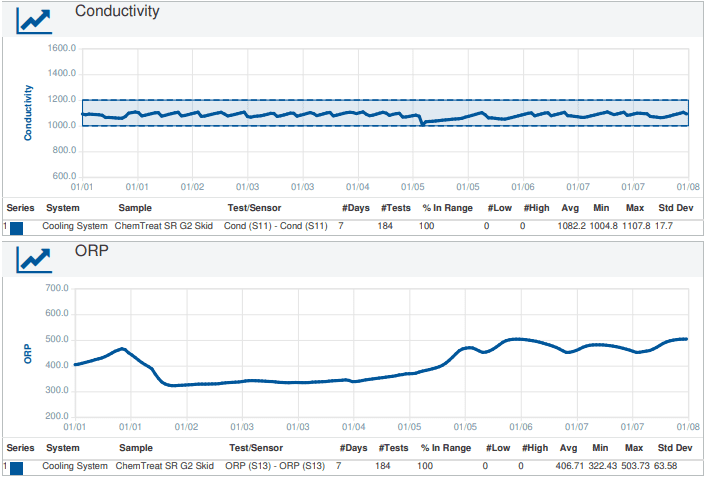

With the installation of the second-generation Smart Release solid cooling feed system, the customer can now receive daily summary reports that trend KPIs and let staff know when more chemical needs to be fed into the system.

Thanks to the enhanced capabilities of this solid cooling treatment solution, the customer is now feeding a more precise quantity of product and has successfully reduced microbiological fouling.

Cooling system trend from the customer’s daily summary report generated in CTVista®+

Results are examples only. They are not guaranteed. Actual results may vary.