Detackification is an essential step in automotive paint processes, one that has evolved alongside paint technology through the years.

Paint Detackification Timeline

The following is a general timeline of paint and detack development through the years:

1950s—1970s

Paint technology: solvent low-solids enamels

Detack technology: high-alkalinity programs with sinking solids

Early 1980s

Paint: high-solids enamels

Detack: clay, aluminum, and tannin; move to solids removal

Late 1980s

Paint: introduction of water-based base coasts

Detack: move to melamine; majority of programs deal with solids removal

Early 2000s

Paint: moves to 2k clear coat

Detack: melamine; move towards environmentally-friendly technologies

Mid-2000s

Paint: water-based primers, base coats, and 2k clear coats

Detack: reduced usage of melamine; growth of green technologies

2010s

Paint: primerless applications

Detack: green technologies dominate

The most recent developments in paint detack have many benefits over traditional programs. Reducing sludge waste, blowdown, product consumption, and total suspended solids in water reduces costs associated with water, freight, and booth cleaning.

ChemTreat’s patented paint detackification technology offers the following benefits over standard treatment options:

- As a starch component derived from corn, it is considered a biological renewable resource

- Eliminates the use of formaldehyde in the treatment polymer for reduced toxicity

- Reduces sludge volume and moisture

- Reduced usage leads to reduced transportation costs

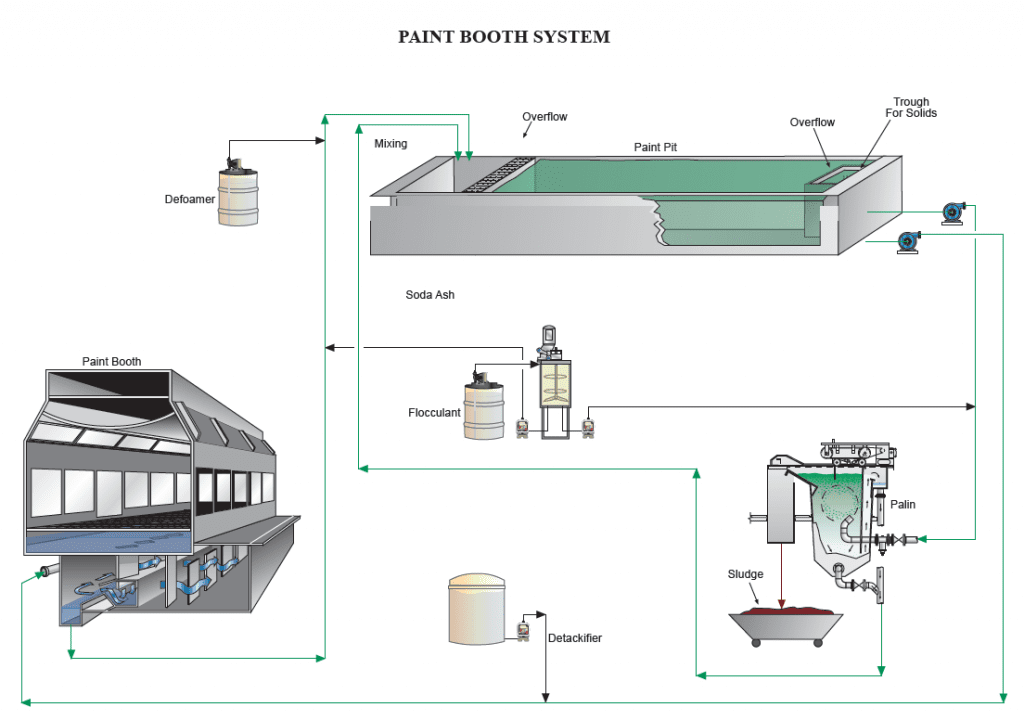

We also offer defoamers, polymers, biocides, and pH-management products for comprehensive paint booth treatment.

Please contact ChemTreat for assistance in designing a treatment program customized for your application. Like all other technologies, due diligence is necessary to determine the feasibility for utilizing methods. Always consult your equipment manuals and guides.