The Problem

A leading food processing plant in the southern US had a familiar food safety problem Quaternary amines (quats) are the desired biocide for cleaning food processing equipment because they offer effective and long-lasting protection against bacteria. But when equipment is washed down after cleaning, un-neutralized quat enters the wastewater system and poisons aeration basin bacteria.

Without the means to accurately measure free quat entering the wastewater system, plants cannot ensure quat neutralization before it reaches the biosystem. The customer could not use the amount of quat desired for equipment sanitation because of the potential negative impacts on the wastewater biosystem. Whenever they tried to increase the quat level, problems arose with biological oxygen demand (BOD) conversion, sludge settleability, and aeration basin upsets. The plant needed a way to measure the levels of free quat in the wash water in order to neutralize it prior to the effluent entering the wastewater plant.

The Solution

ChemTreat offered the customer our patented QuatKill technology, which required no capital investment. QuatKill is a proprietary product that includes a test kit and a quat-neutralizing formulation, QK1000. A key driver for this technology’s success is the colorimetric test kit that quickly and accurately measures free quat in the wastewater over a wide concentration range.

A competitive offer was a clay-based solution to neutralize the quat with a costly upgrade to the customer’s feed equipment. QuatKill proved more cost-effective and did not limit the amount of quat the customer could use to ensure food safety. The customer conducted a trial with ChemTreat’s QuatKill.

The Results

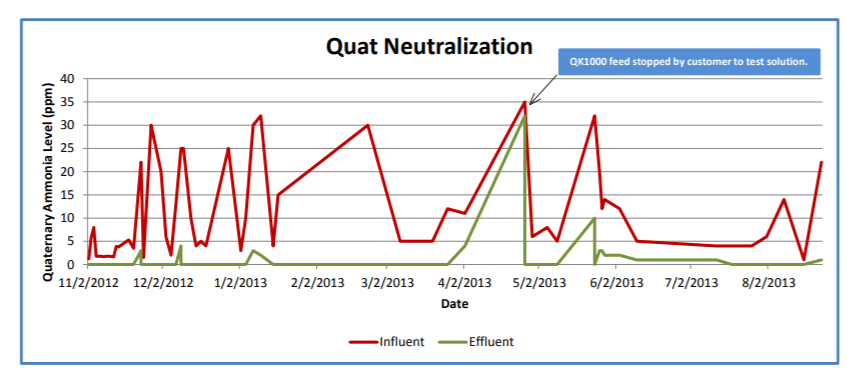

During the QuatKill trial, the customer fed the desired quat amount for equipment sanitation. Quat levels entering the wastewater stream increased from 3 to 35 ppm, but dropped consistently to 0 ppm after the QK1000 neutralizer application point. The QuatKill test kit provided accurate measurement of the un-neutralized quat, and QK1000 rapidly neutralized it, preventing negative impact on wastewater system performance.

The benefits of the treatment program included:

- Consistent BOD conversion rates

- Dramatically improved sludge settleability and a healthier sludge bed

- Aeration basins that did not turn over during summer-to-fall temperature changes

- Sanitation improvement when quat was no longer a limiting factor

Upon completion of the trial, the customer decided to eliminate the QK1000 neutralizer to validate the success of the ChemTreat solution. Within a week, the wastewater plant had to shut down because of bacteria loss in the aeration basins. The plant faced a potential production shutdown, so the customer immediately restarted QK1000 treatment.

After validating the performance of our QuatKill technology, the customer signed a multi-year contract with ChemTreat for wastewater treatment.

Results are examples only. They are not guaranteed. Actual results may vary.