A large chemical plant in the southeastern US started using QuadDetect technology in their cooling system before a two-month maintenance shutdown. Plants coming on-line from an extended shutdown often experience higher levels of contaminants (iron, suspended solids, process contamination, etc.) during startup, contributing to system stress and increased polymer demand.

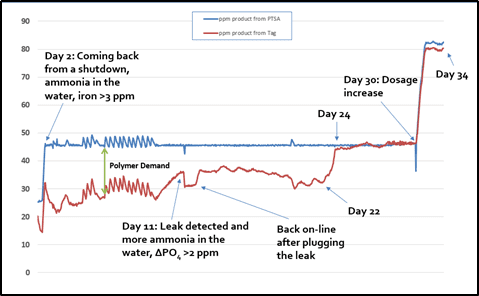

The below graph shows the significant initial polymer demand, demonstrated by the difference between the product levels using legacy PTSA fluorescent tracing and QuadDetect on-line polymer measurement.

When the system cycled up and took in fresh water, the active polymer levels increased as demand was reduced. On the 11th day, a process leak and subsequent contamination in the cooling system increased polymer demand once more.

The leak also led to an increase in cooling water pH and possible calcium phosphate formation in the bulk water, correlating to the increase in polymer demand.

The process leak was quickly corrected, and the plant returned back on-line. However, the contamination and stress continued causing high polymer demand between days 14 and 22. Once the system demand was met, the QuadDetect tagged polymer correlated well with the PTSA tracking.

Results are examples only. They are not guaranteed. Actual results may vary.

Contact us to learn more about QuadDetect and our other water treatment offerings.